Who's Got Your Back?

Increase plant productivity, avert asset failures and minimize downtime. Motornostix® is the industry-standard solution for shredder monitoring. With full-service and cost-effective shredder health and performance management, we monitor our customers' equipment 24x7. Who's got your back?

Do More With Less

Staffing challenges, changing industry economics and supply chain constraints require that you do more with less. Sometimes with a lot less. And without compromising the health of your critical plant assets. Motornostix® is there to help you keep your finger on the pulse of your operation.

Piece Of Mind

We are the missing piece in your plant health and performance management. Quietly running behind the scenes and telling you what you need to know, when you need to know it. So you can focus on running your business and staying ahead of the game. Motornostix®, your peace of mind.

About Us

For more than twenty years we have been on a mission to maximize shredder performance while caring for asset health. Our customers rate amongst the best performing plants for their mill size in the industry. Continuous monitoring of your plant assets helps identify opportunities for improvement and predictive care that has resulted in many early-warnings to our customers over the years, preventing failures and protecting and extending the life of their valuable plant assets.

Our Mission

We provide best-in-class shredder health and performance monitoring equipment and services and leverage our extensive industry experience in support of our customers.

Our Plan

We partner with you and your team using our tools and technologies to continuously measure, improve and refine shredder performance while maximizing asset health.

Our Vision

Your shredder plant, highly profitable and astonishingly productive with wonderful asset health and safety resulting from predictive maintenance practices.

Services

Knowing when to run equipment and when to repair equipment can mean the difference between safe operation with long equipment life versus less desirable alternatives such as unplanned downtime and catastrophic failures. Skilled operators often feel or sense equipment issues but have no way to know if their sensations are correct or to communicate their sensations to management. Motornostix® sensors are connected directly to the shredder and to the drive motor[s], looking at three axes of bearing data, and can sense issues reliably to aid in problem detection and identification. We also contribute to efficient plant operation by monitoring values such as power consumption and output, offering reports on these items to improve daily throughput.

Data Safety and Access

• We store your data in a Tier-3 facility so it is safe, secure

and accessible.

• It is accessible via any device that can connect to the

Internet and run a browser.

• We have resolved a number of issues over the years by

providing vendors access to customer data for troubleshooting

purposes. This has reduced the lead time to resolution, greatly

assisted with root cause analysis and limited the cost involved

since often times no vendor visits were required. This has been

particularly helpful with vendors who are not state-side, like

Alstom, Actom and WEG.

Alarms

• From the monitored data, Motornostix® provides

alerts, alarms and information to protect the health and safety

of personnel, equipment and the environment around metal

shredders.

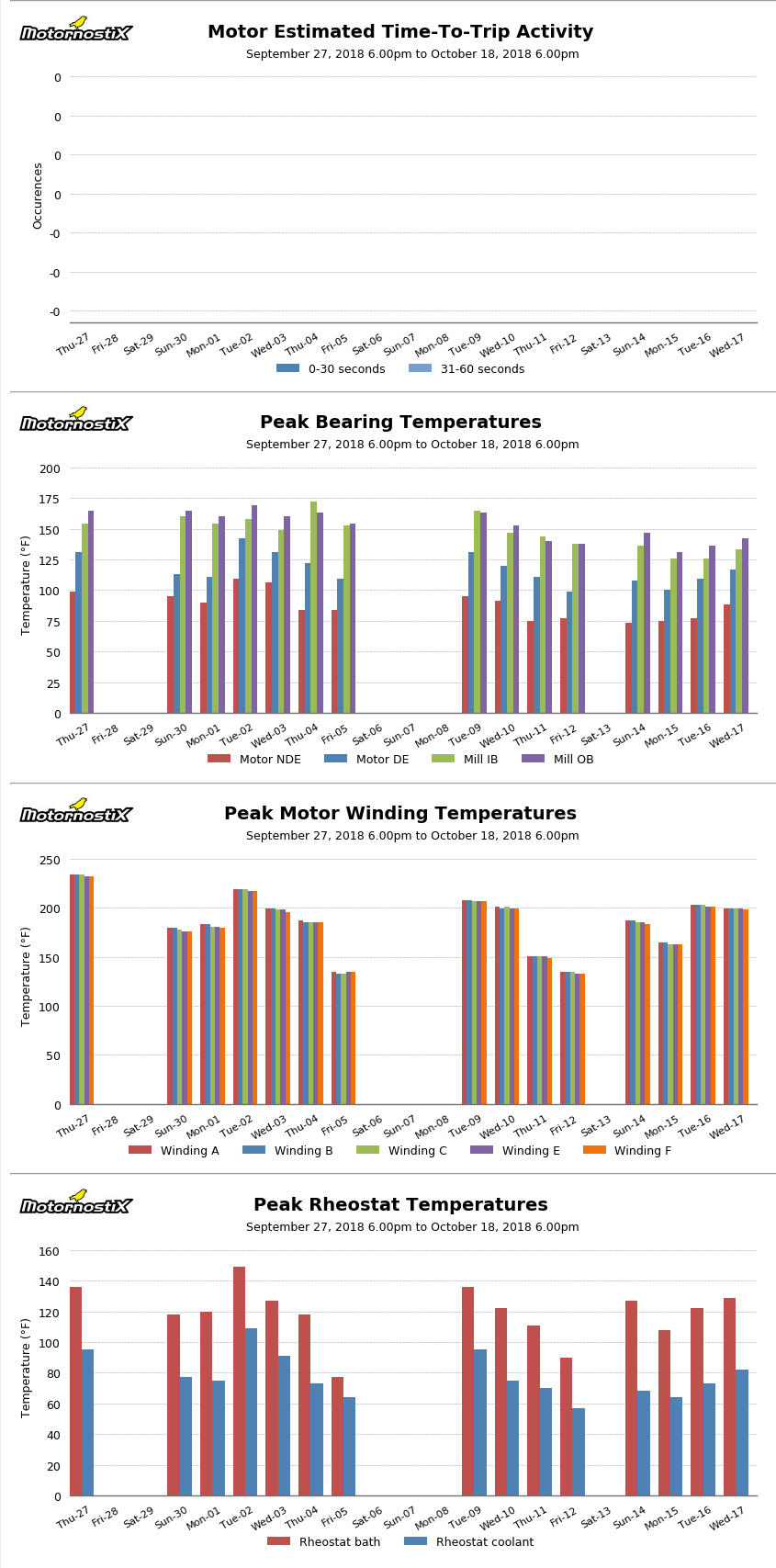

• All key measurables both from our sensors and the Multilin are

collected, measured and monitored in real-time. Alarms are

raised to notify you of developing health conditions during your

production run. These can be anything from surfacing flaky RTDs

(e.g. damaged, over-temperature or loose terminal connections)

to vibration alarms indicating damaging vibration impacting

machine health.

Analysis

• Automatically mining data on the backend.

• Tools for analysis if needed.

• Analysis if needed.

• Expertise if needed.

• The Motornostix® system captures vibration

waveforms (think bearing MRI or X-Ray) on each bearing in all 3

axes (axial, horizontal & vertical) and deconstructs these

comprehensive measurements into their components parts (e.g.

comparing synchronous vs non-synchronous energy as a basic

example) to evaluate bearing health over time. Waveforms are

captured at idle on every run day, thus forming a comprehensive

picture of machine health over time. And all of this information

is available via our portal to you, and your vendors as

permitted.

Monitoring

• All your shredder health and performance data is streamed to

our Tier-3 Data Center where it is available to you 24x7.

• We keep ALL your history online. Want to compare last month to

this month? It’s online. So is last year and the year before

going all the way back. This is a really powerful feature of our

system typically not provided by process control systems at

recycling plants.

• This is one of the main reasons that our large corporate

customers really like our system, since ALL the data for ALL the

plants is available ALL the time at your fingertips.

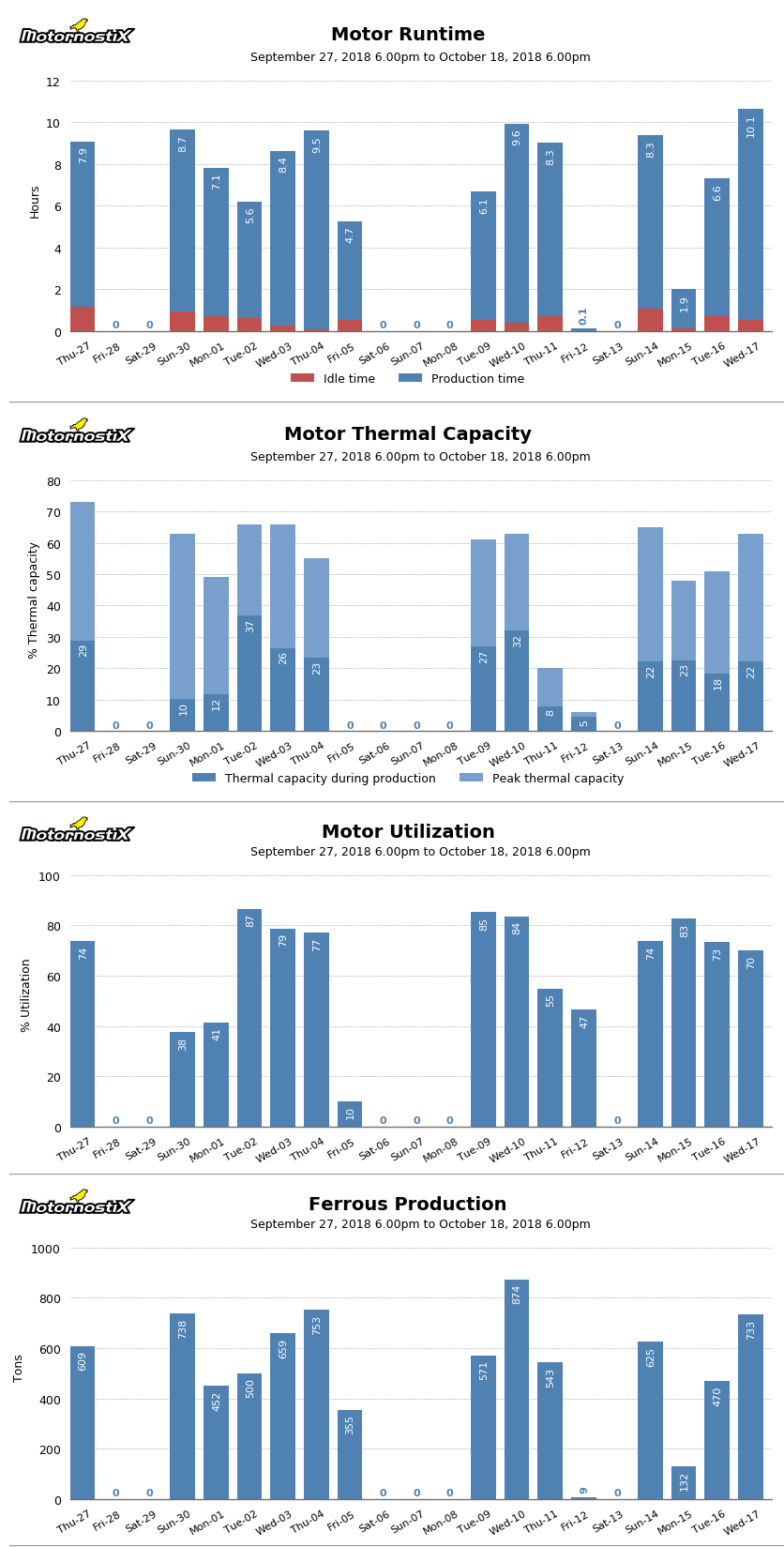

Reporting

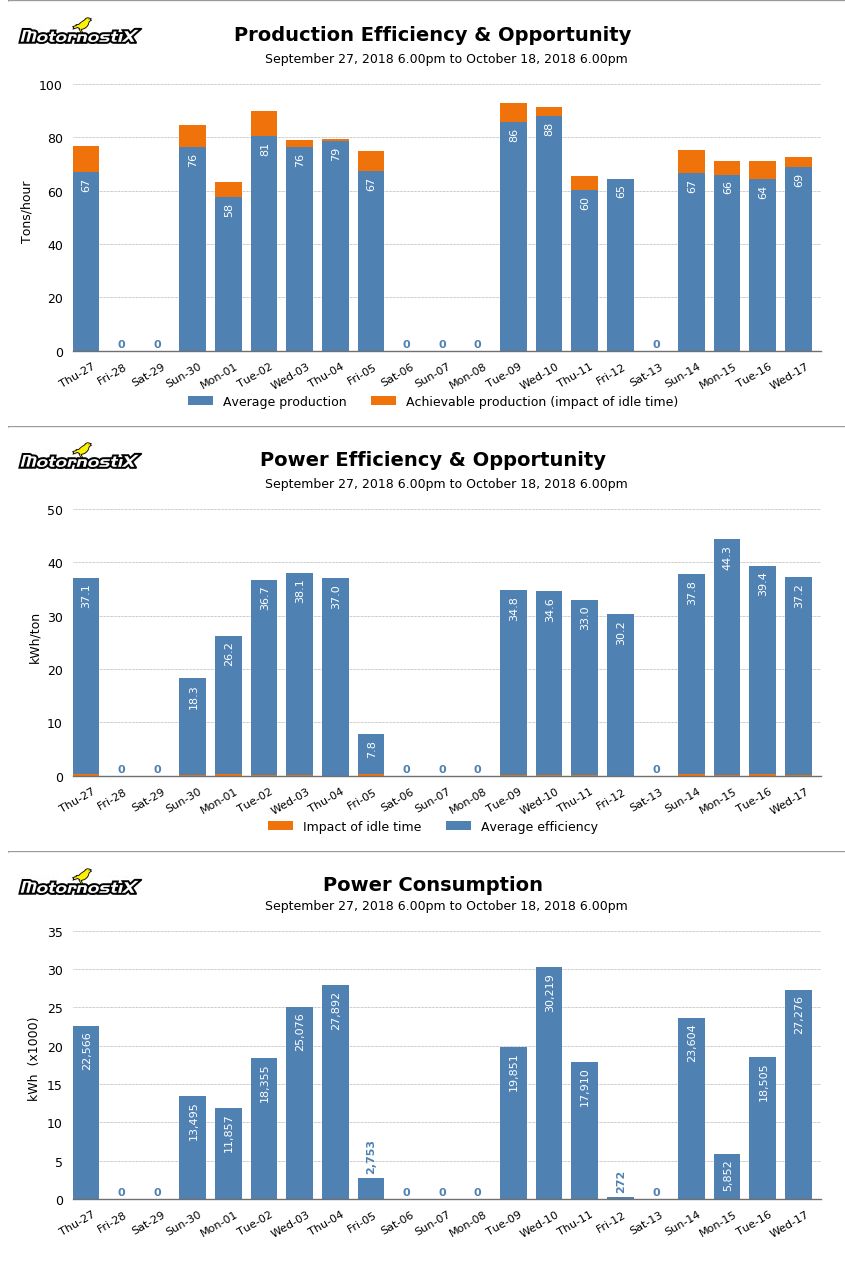

• We provide you with two daily reports for each site – the

performance

report

covers exactly that – how well did the site perform against

expectations for the last 24h window (defined by you)? This

information includes runtime, idle time, motor utilization,

thermal capacity, production output and electrical efficiency.

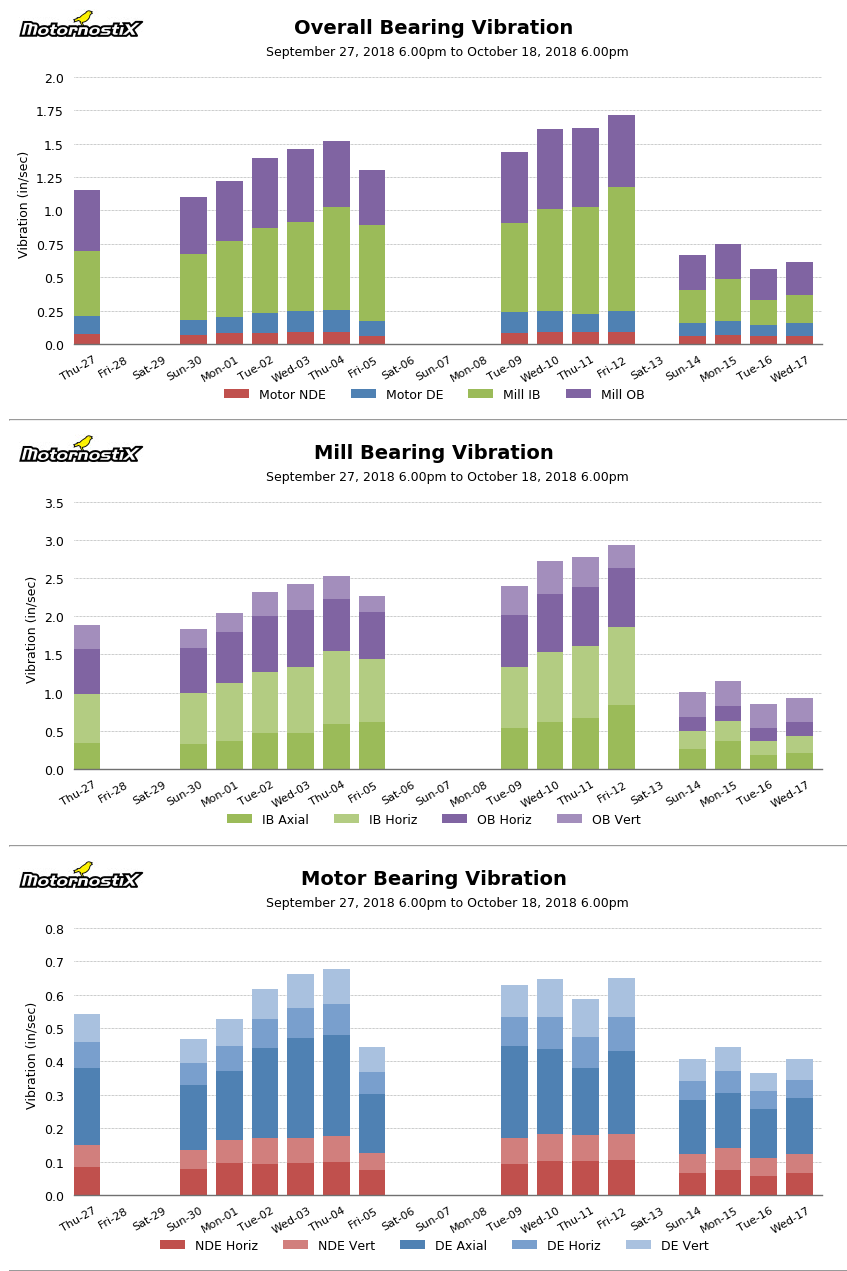

• The

health report

details machine health metrics to answer the question – what was

the impact on machine health for the performance achieved? The

health report also surfaces developing machine health

conditions. The report shows vibration data across the drive

train in an easily-consumable format so you can compare

day-on-day and investigate and identify associated root causes.

• Motornostix® provides notifications of significant

events.

• Motornostix® provides reports of critical

performance.

• Motornostix® provides tools for monitoring and

analysis.

• Motornostix® provides protection against unplanned

downtime.

• Motornostix® provides protection against

catastrophic failures.

System Reliability

• Industry standards for operation and security.

• The only potential damage to our system generally occurs out

at the mill.

• Our mill sensor and cables are armored and jacketed with an

aerospace thermal fire-sleeve along with a stainless steel woven

braid. This design has proved pretty impervious even to the

destructive nature of the shredding process, but occasionally

damage, either thermal (e.g. mill fire) and mechanical (e.g. car

falls from in-feed chute onto our sensor) occurs.

• Any such damage would require sensor/cable replacement at your

cost.

• If a sensor fails without any observable damage, then we offer

forward replacement of the part at our cost.

• Whilst it varies from site to site, mill sensor lifetime is

often measured in years.

• If some other component of our system fails (e.g. a computer)

without overt damage, then we cover the cost of the replacement

item.

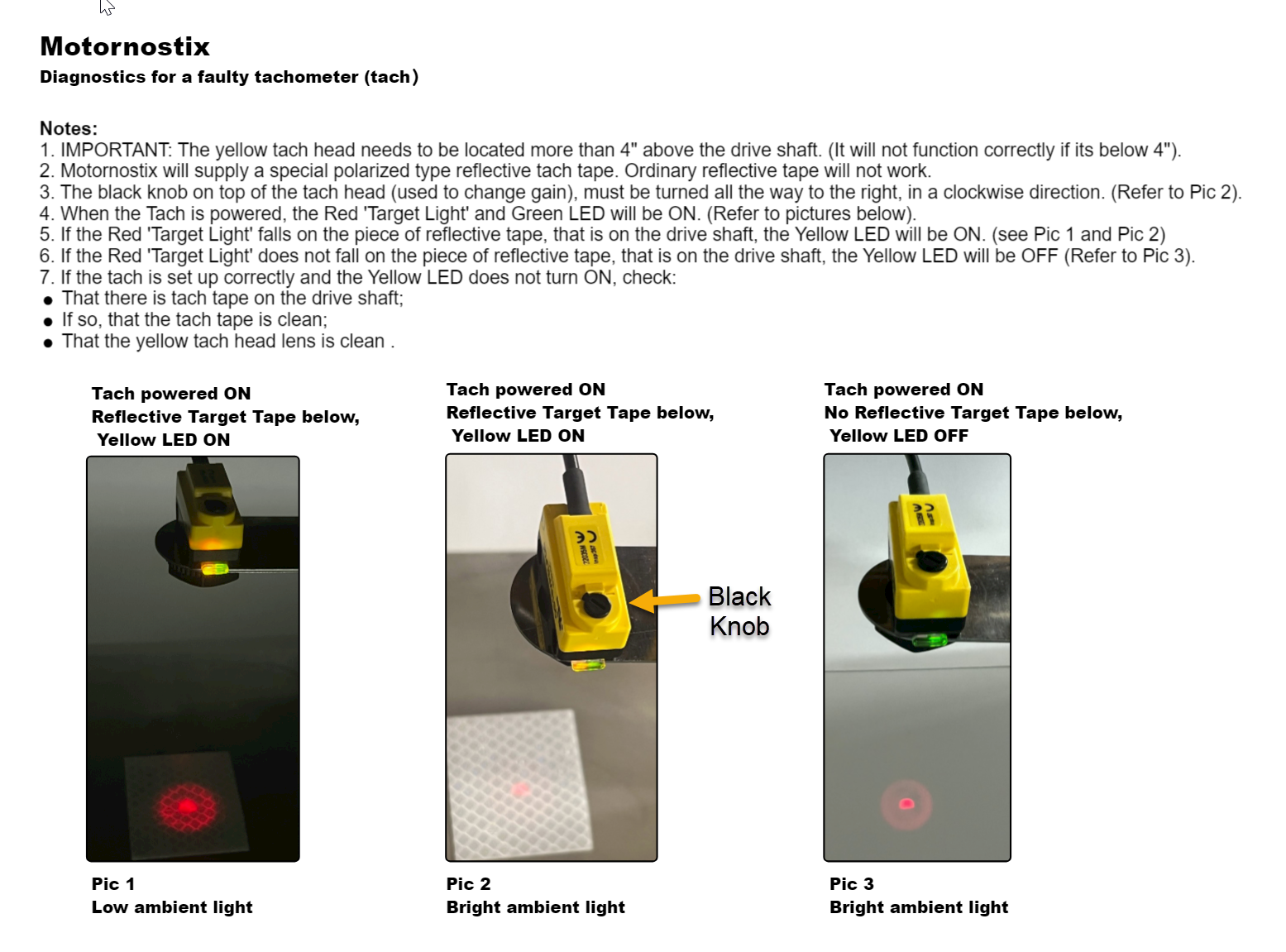

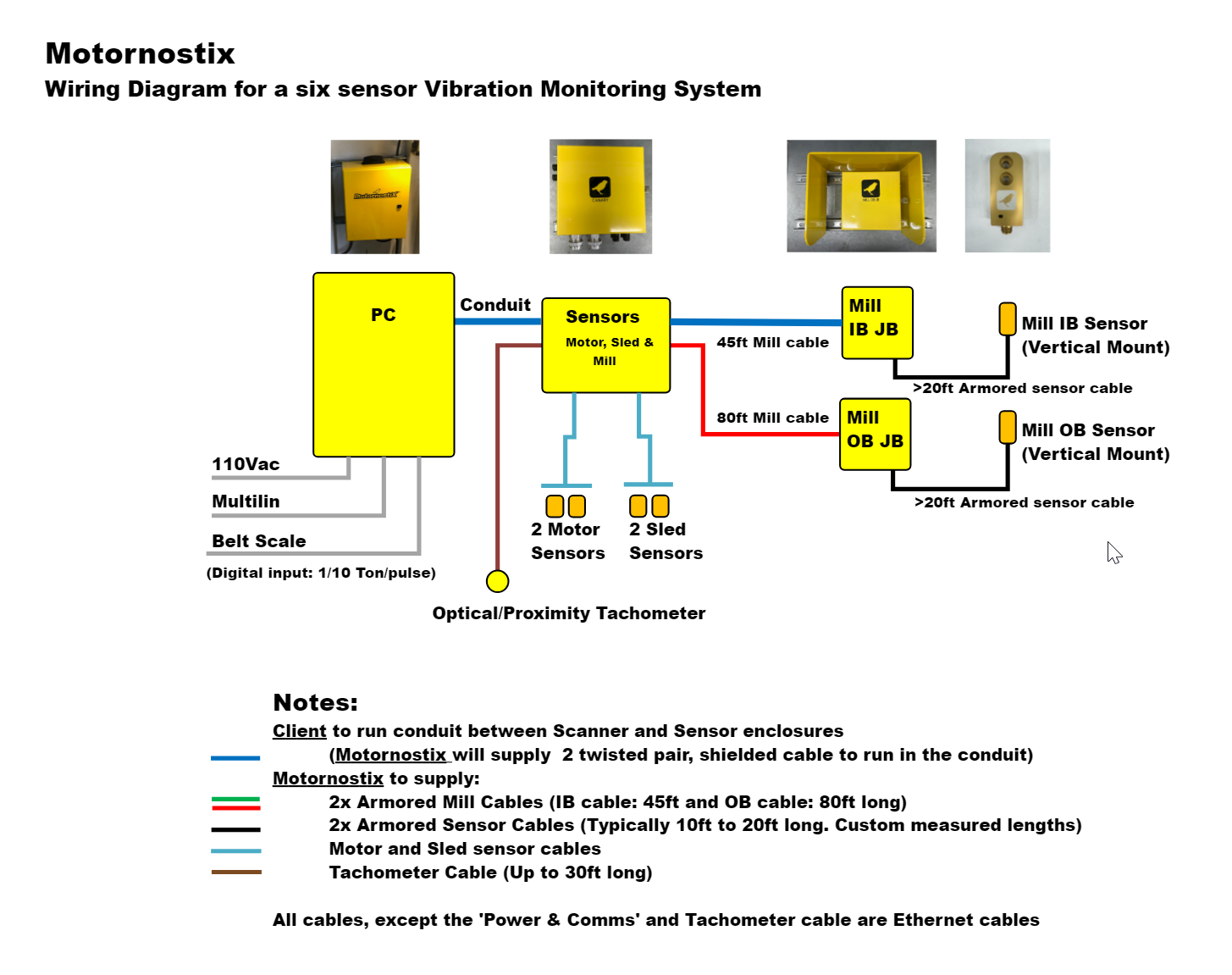

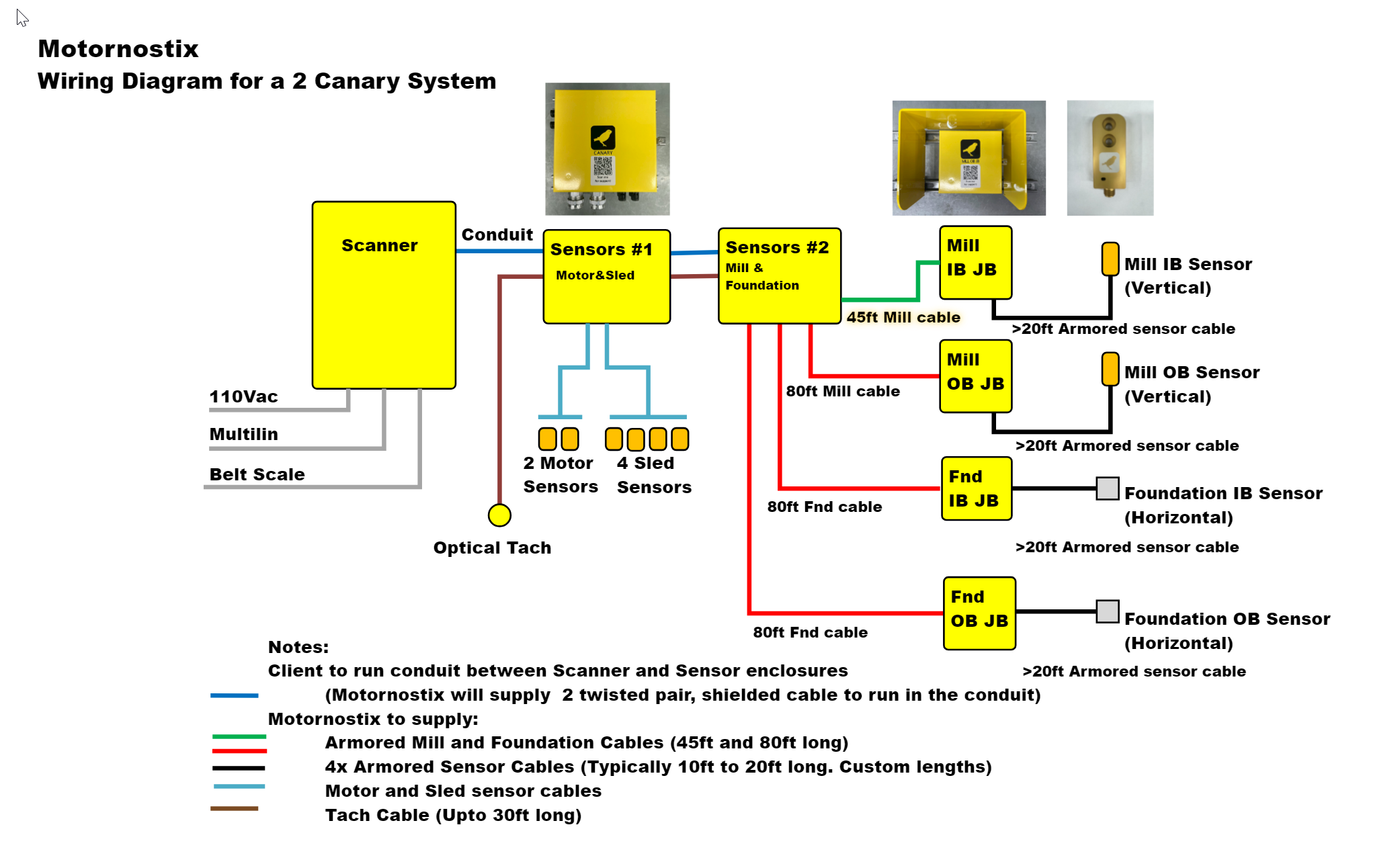

Installation

• The installation cost includes all the Motornostix®

specific equipment to be installed at each site including cabinets,

power systems, computer equipment, cables and sensors.

• Our system comes pre-assembled (think Legos) to ease installation

and minimize downtime.

• We generally need some help from your site electrical contractor

to provide power to our cabinet, running conduit if required, and to

assist with welding our junction boxes out at the mill.

• An installation takes approx. 2-3 days depending on existing site

infrastructure, and most installations typically take place over a

weekend to minimize plant downtime.

Facts

Our commitment to our customers success is evidenced by our longevity in this industry.

Continuous

Monitoring

Hours

Data

Points

Collected

Hours Of Support

Hours of

Experience

Known by the companies we keep

Contact Us

Please contact us for more information. We love to hear from customers and potential customers alike.

Address

P.O.Box 498136Cincinnati, Ohio 45249, USA

Phone Number

513-334-3550

sales@motornostixusa.com