When running sensor cables out on the shredder, Motornostix® typically uses a mix

of four approaches to secure cables to the shredder.

Option 1: Using Unistrut with Unistrut 90 deg angles, angles that have pre-punched 1/2" holes, making it easy to fasten sensor cables to the 90 deg angles, using stainless steel ties. Below are two pictures as a reference.

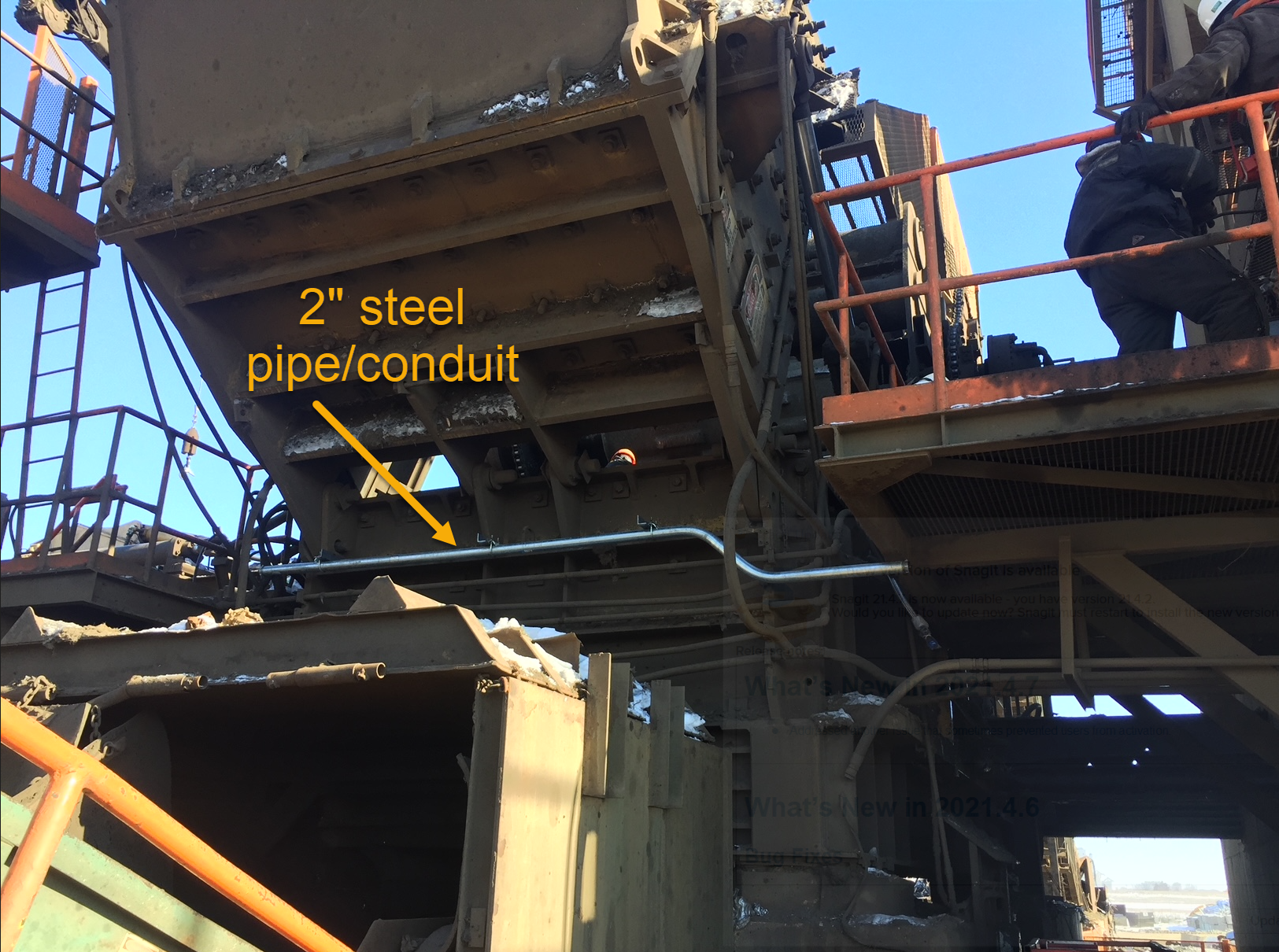

Option 2: Running our cables through a 2" steel pipe/conduit or 2" angle iron under/alongside the boardwalk. Both the 2" pipe or 2" angle iron will protect the cable from shredder debris. One can use a stainless steel ties to secure the cables to the underside of the angle iron.

Option 3: Run sensor cables below hydraulic lines and attach them to the hydraulic lines, using stainless steel ties.

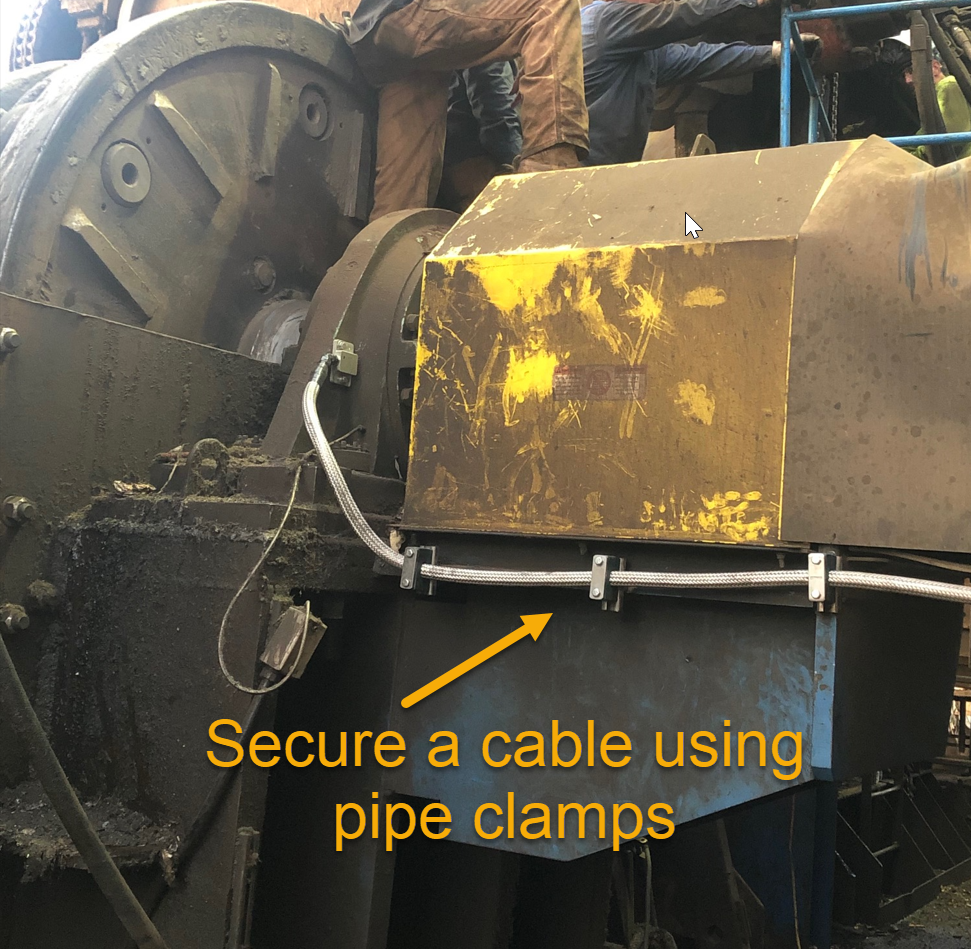

Option 4: Secure a sensor cable using pipe clamps.

One thing to bear in mind is that the mill sensor cables should be run under the shredder drive shaft were possible to give maximum protection. See picture below.

Lastly, regarding wiring up the new Canary unit, these are the positions on the Concentrator Board where each sensor is to land:

| Sensor | Position on PCB |

|---|---|

| Motor Non Drive End (NDE) | Sensor 1 |

| Motor Drive End (DE) | Sensor 2 |

| Sled DE left | Sensor 3 |

| Sled DE right | Sensor 4 |

| Mill Inboard (IB) | Sensor 5 |

| Mill Outboard (OB) | Sensor 6 |

Once you have mounted the mill bearing sensor housing and corresponding Junction box (JB), please measure the length of both the Inboard (IB) mill bearing cable length and the outboard (OB) mill bearing cable length and Motornostix will make you custom length cables. These cable lengths should ideally not be longer than 20 ft. They are generally shorter than 20 ft. Also, add about a foot in length to each sensor cable, so it does not come up short when the sensor cable is secured.