Clamp the vertical mill sensor onto the mill bearing housing, in the position where it will

be mounted.

If the PT 100 temperature sensor cable interferes with where the vertical mill bearing

sensor is to be mounted, mount the vertical mill sensor on the other side of the bearing

housing.

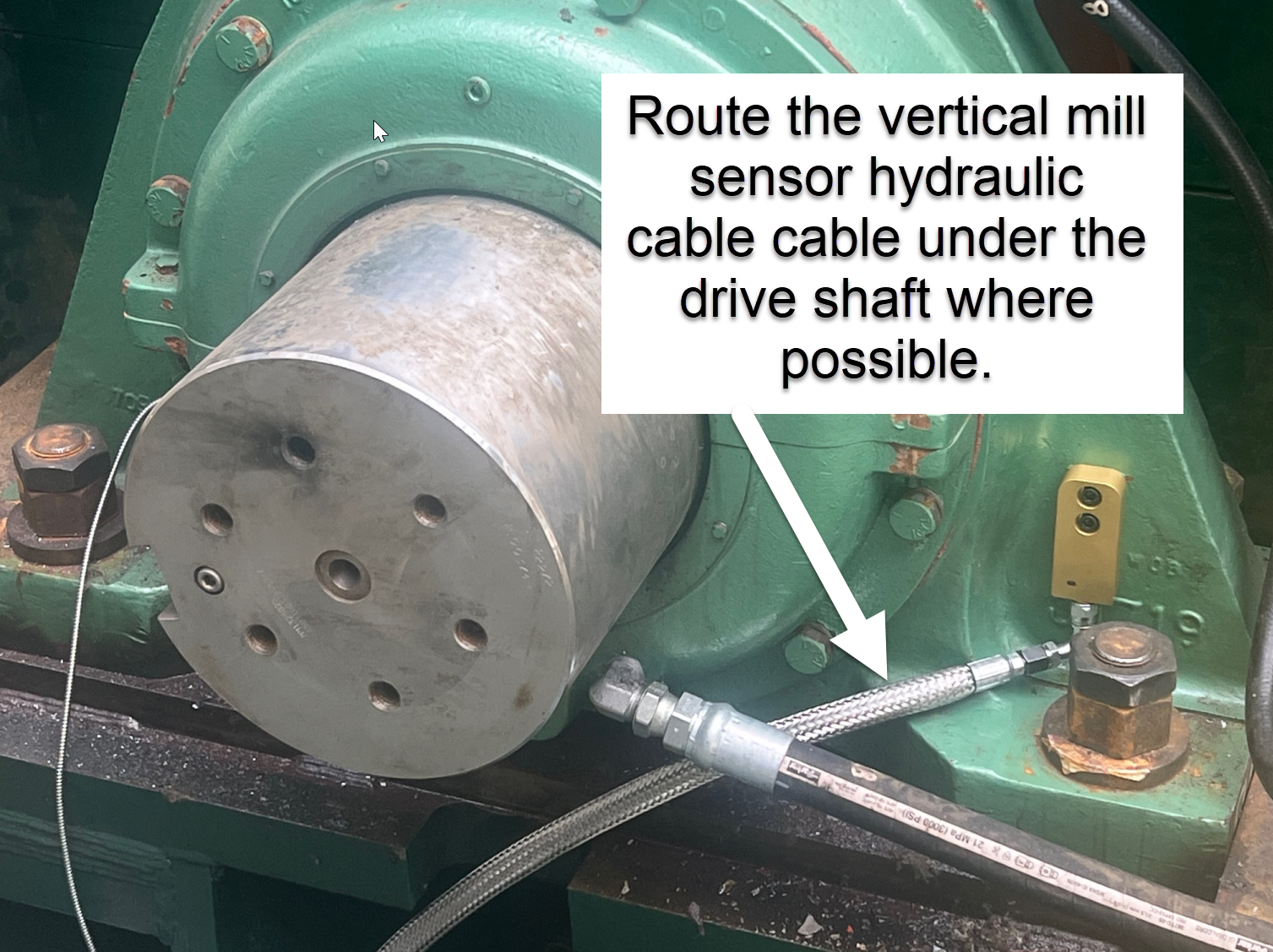

Route the hydraulic hose attached to the vertical mill sensor under the drive shaft where

possible, for better protection.

Ideally, the hydraulic hose cable should be routed from the sensor, under the driveshaft and

then run under the boardwalk to the relevant Junction Box (JB).

Make sure that the hydraulic hose cable is able to move more than 4” inches when it is

secured to the boardwalk or shredder. to allow for shredder movement.

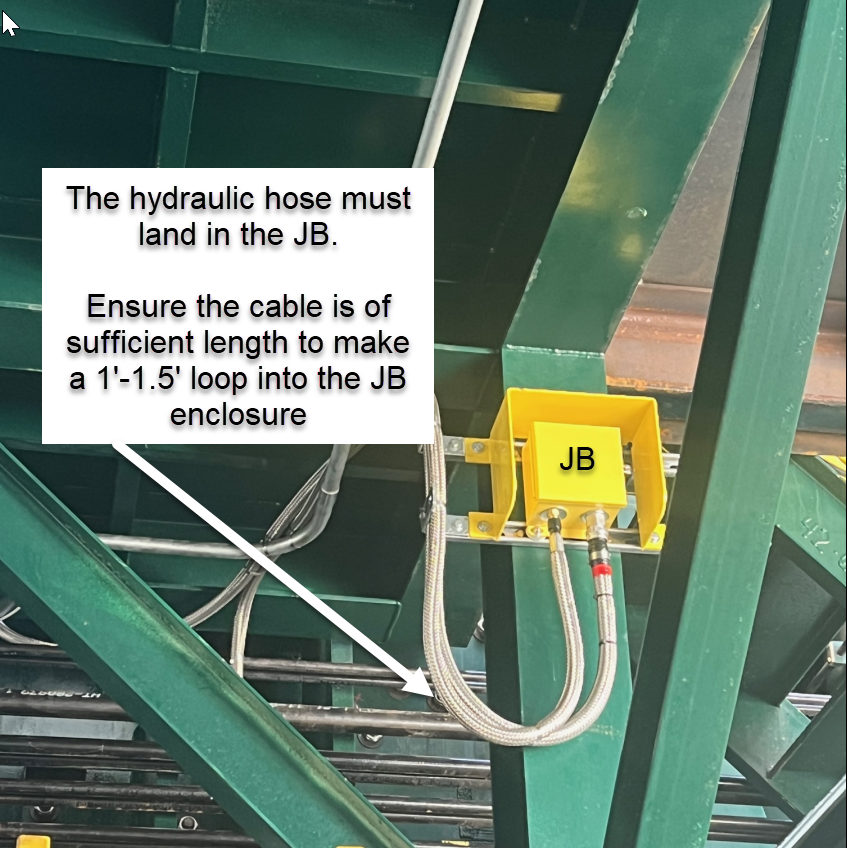

The hydraulic hose cable lands directly into the relevant JB.

Ensure the cable is of sufficient length to be able to loop it into the JB. (The loop radius

is typically about 1ft – 1.5 ft).

It is suggested that 1ft be added to the overall cable length to accommodate any sharp bends

in the cable when it is mounted using stainless steel cable ties.