A working tachometer is critical to our data collection process as it determines how often our software collects data and whether our software collects waveforms or not.

For proper operation

• The tachometer needs to clearly see the tachometer tape on the shaft so the light can be

reflected back to the tachometer.

• It can't be too close nor too far away. Five to six inches is a good distance.

• The tachometer tape needs to be clean.

• The tachometer lens needs to be clean.

• The tachometer needs to be properly aligned. Regarding alignment, the tachometer needs to

be pointed at the tachometer tape when the tachometer tape is where the tachometer is. The

red dot from the tachometer needs to be on the tachometer

tape.

• If it works (the yellow LED blinks) when the tape is

waved under the tachometer then it is

working.

• Often, the problem is the tachometer tape is dirty or the tachometer is too close, too far

away or not properly aligned.

• The tachometer head has a small black sensitivity adjustment trim screw on the top of the

tachometer head. It needs to be positioned to its limit in a clockwise direction.

Notes

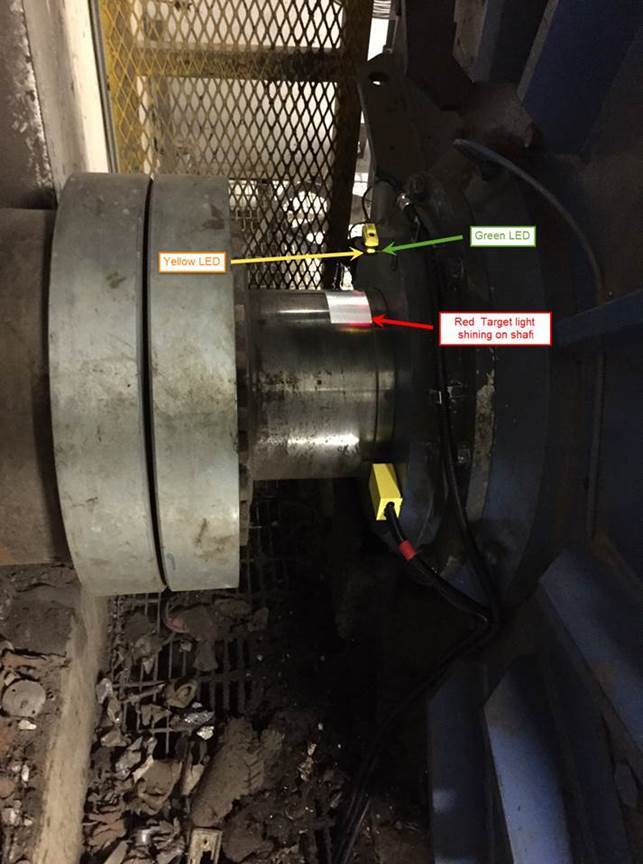

• The Green LED indicates Power to the Tachometer is ON.

• The

Yellow LED

turns on each time the reflective tape passes under the tachometer and

then

turns off again once the reflective tape has passed.

•

Red Target Light

should be ON if the Green LED is ON.

• Tachometer head is mounted directly above the top of the drive shaft.

• The bottom of the yellow tachometer head must be 5” above

the top of the drive

shaft/tachometer tape.